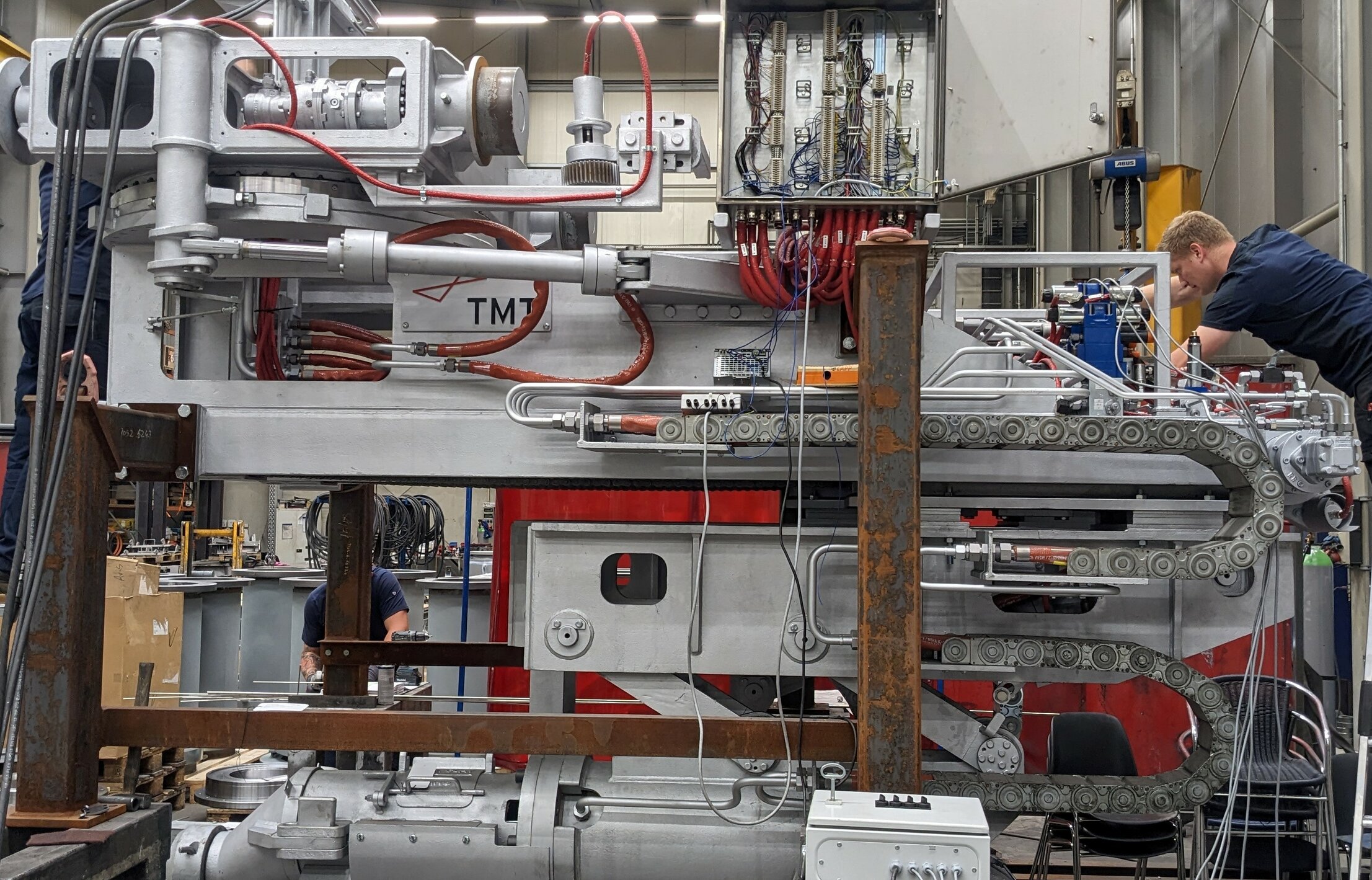

TMT successfully manages machine overhaul of combined TMT tapping equipment in record time

Due to the excellent cooperation of the project teams of a German customer and TMT overhaul of a TMT Clay Gun and Taphole Opener could be completed within a record time of only 6 months. The special challenge was to get the machine back to site as fast as possible within the set budget.

After fire damage at the furnace the machine had been partially destroyed and therefore had to be taken out of operation. No persons had been injured in the accident.

Since the machine is urgently needed at customer's plant time was one key factor in the project. After an inspection of the machine parts to be renewed and parts to be reused after proper reconditioning were determined. Thanks to the expertise of TMT's specialists gained in many years in the field of overhauling projects parts that necessarily had to be replaced could be clearly defined. In addition to the time savings project costs were also significantly reduced compared to a new machine.

During the upcoming shutdown, the machine will be assembled and put back into operation by the end of the year with the support of experienced TMT supervising personnel.

For further details please feel free to contact us by telephone under +49 271 4014 223 or by E-Mail addressed to Mrs. C. Dirlenbach (mailto:claudia.dirlenbachnoSpam@tmtnoSpam.com).

TMT - Tapping Measuring Technology - a joint venture between DANGO & DIENENTHAL and PAUL WURTH, two globally renowned companies operating in the iron and steel market, draws on decades of experience and comprehensive expertise to develop ground-breaking solutions for tapping-, measuring- and process technology used in blast furnaces and ferro-alloy furnaces. Our prime objective is to offer our customers equipment with the highest ROI rates in our industry.