Charging Data

Probes for level measurement

and for charging control

Continous stockline level control

Combinations of mechanical and radar stockline indicators allow reliable measurement of the burden level and its descend speed under all operating conditions and during blow-downs.

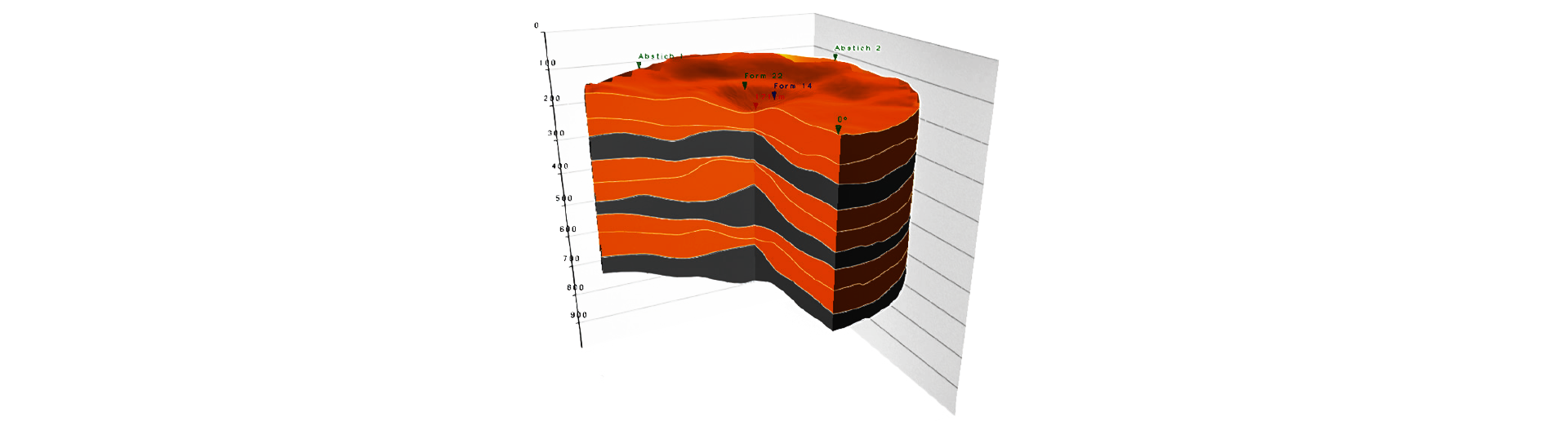

Real 3D surface measurement

Continuous measurement after and during charging at highest resultion

Fast and efficient

No charging time loss as well as one complete surface measurement every 20 seconds

Compact and simple design & maintenance friendly

No protrusion into the BF top cone area, no potential interferences, maintenance possbile with furnace on blast, no platforms required

TMT 3D Topscan™

- Live 3D burden surface monitoring

- Detection of all asymmetries

- 3D layer model

- Areal burden descent speed

- No parts penetrating into top cone area

- Avoids interference with burden charging

- Fast and continous (24/7) measurement

- Highest resolution

- Maintenance possible with furnace on blast

- Better understanding of process leading to coke savings

- Early detection of anomalies avoiding costly process disturbance

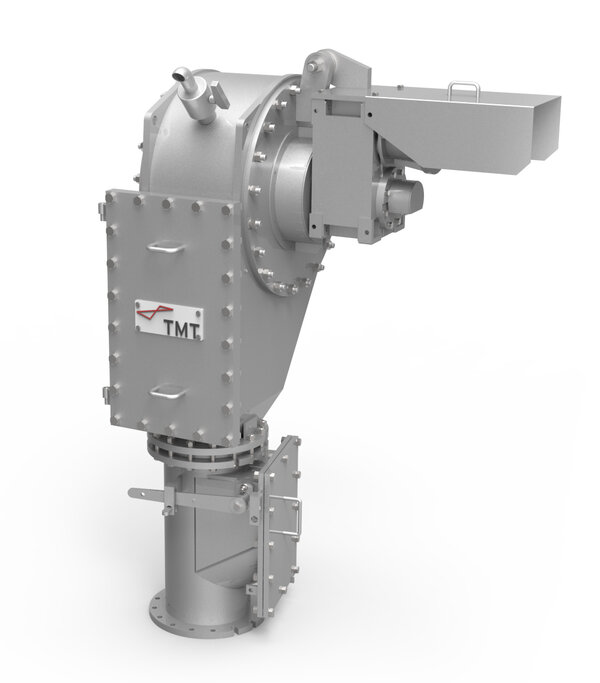

Radar

Stockline Detector

- Continuous measuring of burden level and possible calculation of descent speed

- Measuring range: up to -32 m

- Continuous and reliable measurement of stockline level to control BF charging

- Protected and cooled radar electronics ensure low maintenance requirements and long service life

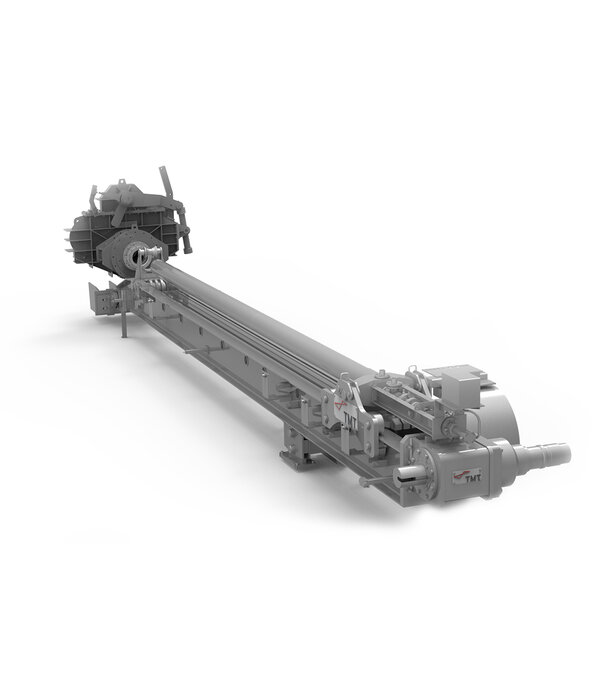

Mechanical

Stockline Detector

- Measurement of burden level and burden descent rate

- Accurate measurements up to -24 m

- Proven reliability

- Low maintenance

- Measurements possible under all BF conditions

Scanning Probe

- Detection of the burden distribution

- Visualization of the burden layers

- Evaluation of burden distribution and its influence on the blast furnace process

- Understand and optimize the blast furnace process together with gas and temperature measurements

Impact Probe

- Detects material falling curve changes

- Enabling the operator to adjust the chute angle

- Reduce production costs by improving the accuracy of the charging

- Can be integrated into existing 2D-profilemeters or installed as separate probe

Integrated solution with dedicated TMT software

The charging data probes are supplied together with dedicated software. The software is able to easily exchange data with the existing automation systems. Dedicated HMI stations are available for process data visualization and condition monitoring of the probe.

Get in Touch

Further information

If you have any requests, questions or needs, please don't hesitate to contact us. We will answer your inquiry as fast as possible.