Process Data

Probes for measurements

Above and below the burden

The temperature distribution and the chemical composition of the gas are reliable indicators for the efficiency of the reduction process. Both are determining factors for operators, seeking to reduce the fuel-rate and to cut the production costs.

State of the Art and easy installation

- Stand alone system and integration in BF expert system

- Modern and modular software architecture

- Monitoring via web interface from anywhere

- Data storage up to 10 years

Process transparency

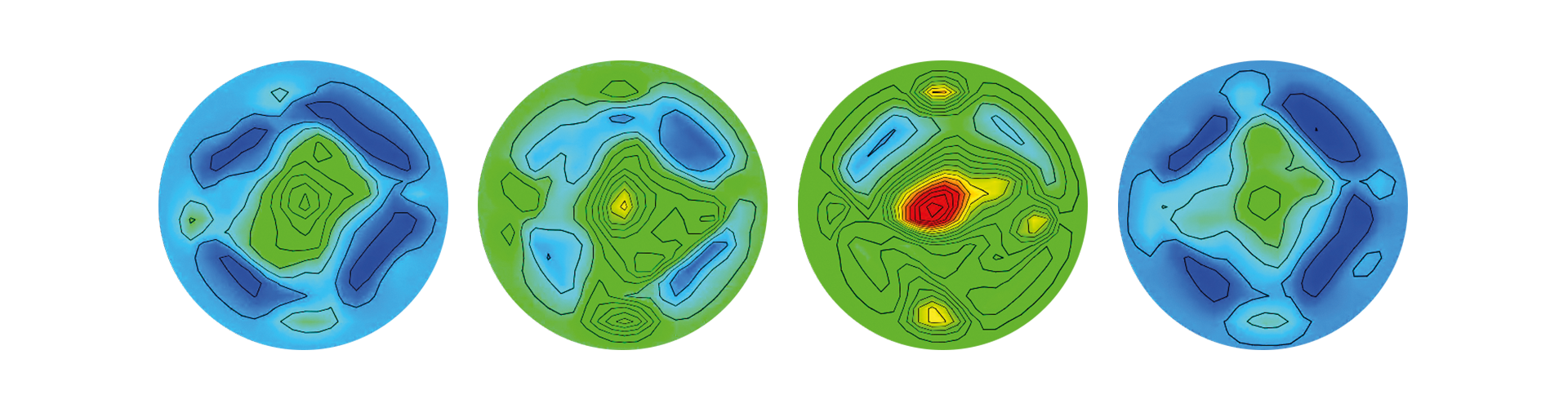

- High resolution 2D top gas temperature distribution update every 4-6 seconds

- Trending of gas channel positions for immediate process correction

- Monitoring of short term process irregularities as well as longterm BF process performance

Accuracy & reliability

- No drift, no calibration

- Temperature range from 0 to 2000°C

- Real gas temperature measurement

- Contactless and self cleaning

- Minimum maintenance requirements

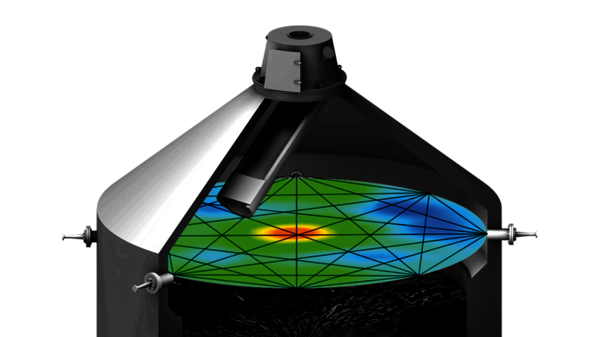

TMT SOMA®

- 2D gas temperature measurement covering the whole burden surface

- Position of gas channel

- Balance between wall and centre flux

- Improved process feedback through visualization of 2D gas temperature distribution in the entire top cone for process optimization and reduction of coke consumption

- Trending of gas channel positions for immediate process corrections

- Detection of abnormal process behaviour

- Longer lifetime and lower maintenance requirements than conventional above burden probes

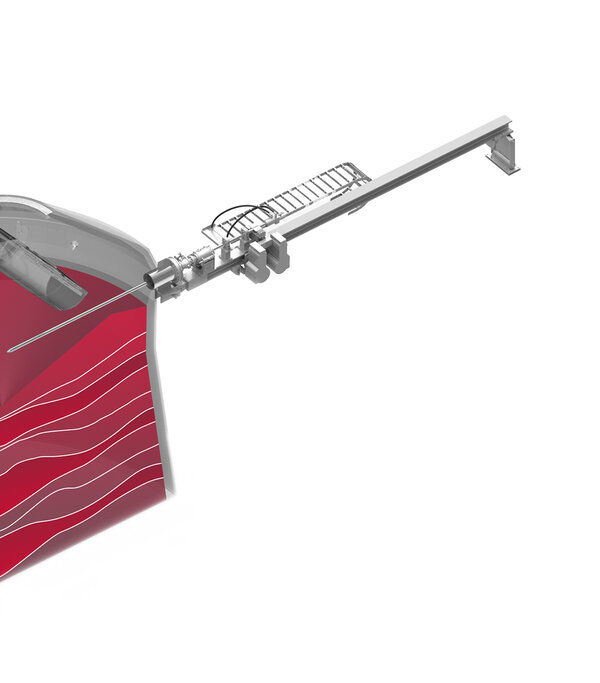

Fixed & movable

above burden probes

- Gas temperature above the burden

- Optional: chemical gas composition in combination with a TMT gas-conditioner and analyzer

- Fully automated gas sampling and analysing sequence for ease of operation

- Water-injection into BF-centre to cool down excessive top gas temperatures

- Optimize the BF-process by allowing to adjust the burden distribution

- Temporary protrusion into the BF to avoid disturbance of charging

- Best suited for combination with TMT-SOMA®

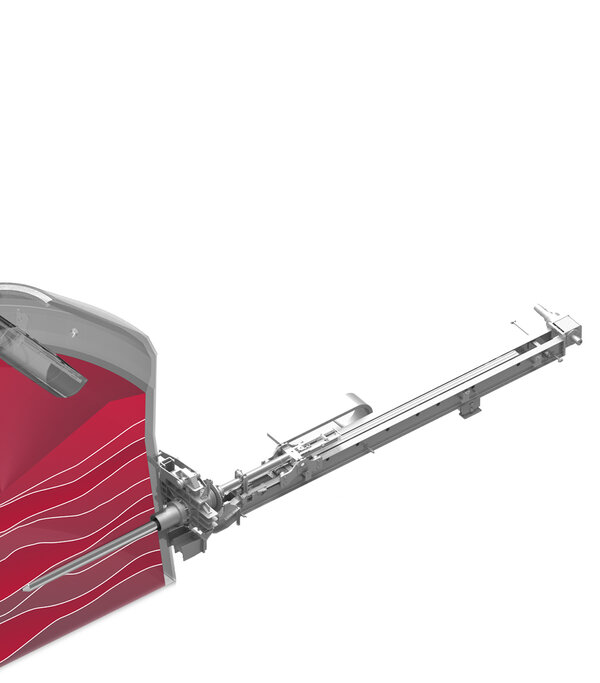

In-burden probe

- Gas temperature and gas composition (CO, CO₂ and H₂; N₂ calculated)

- Measurements are taken below stockline level at multiple points on a BF radius

- Adapting the charging matrix to reduce the coke rate

- Visualisation of CO, CO₂, H₂, N₂ calculated, ETA-CO (gas efficiency) over the BF radius eases the interpretation of the measured data

- Rigid water-cooled design for long service life

Integrated solution with dedicated TMT software

The process data probes are supplied together with dedicated software. The software is able to easily exchange data with the existing automation systems. Dedicated HMI stations are available for process data visualization and condition monitoring of the probe.

Get in Touch

Further information

If you have any requests, questions or needs, please don't hesitate to contact us. We will answer your inquiry as fast as possible.