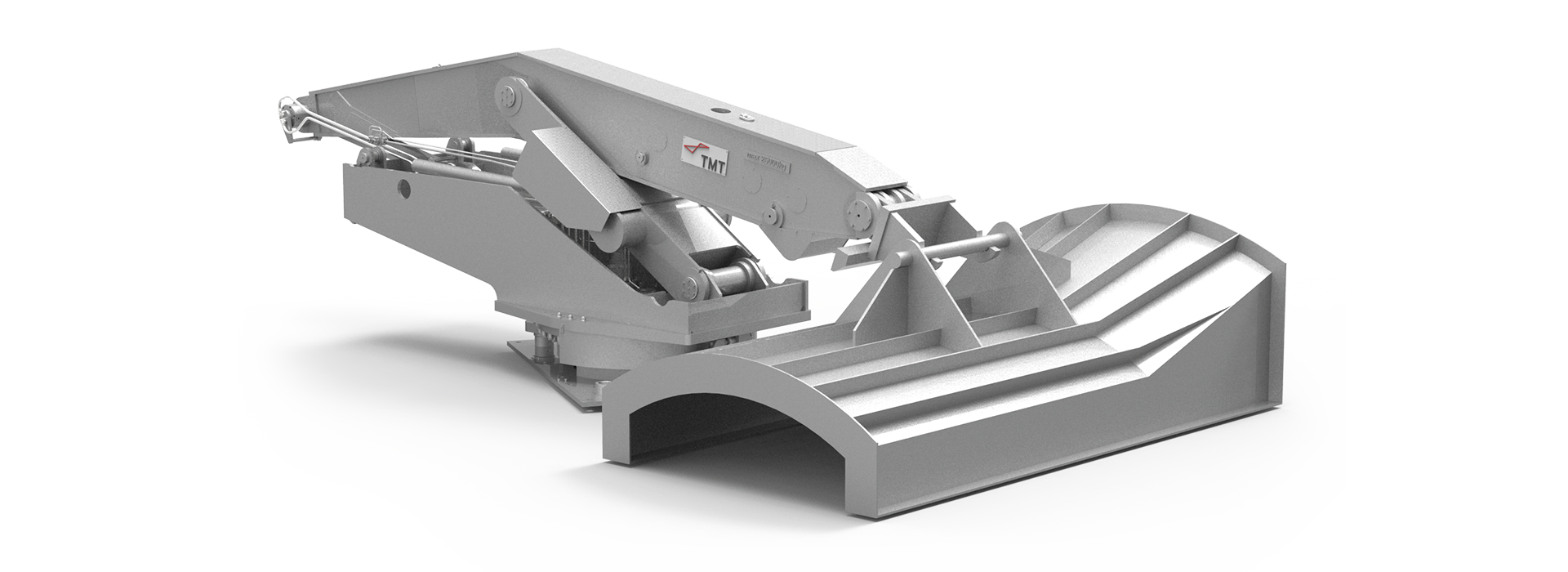

Cover Manipulator

Flexible, safe

and efficient

Your Benefits

Fits any furnace size

Lifting capacity 30 tons and more

Fits any new or existing casthouse layout

Flexible and adaptable designs

Reliable and low maintenance cost

Based on hundreds of furnaces equipped

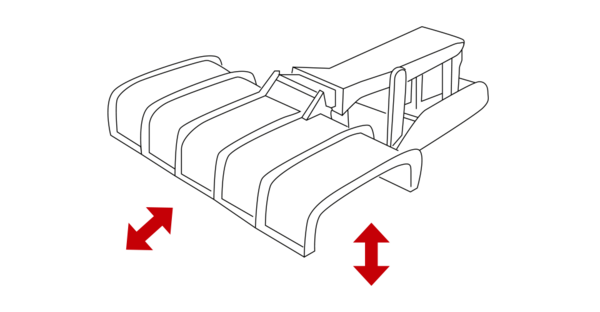

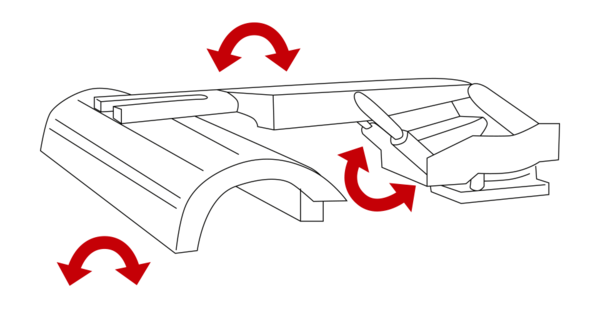

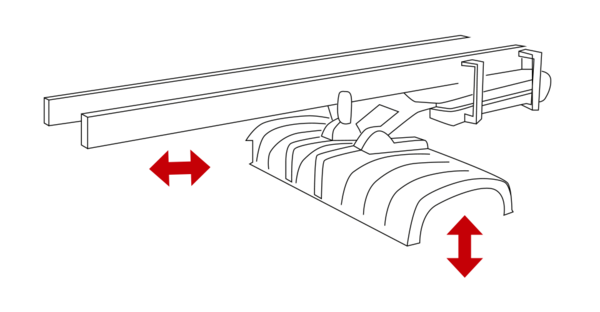

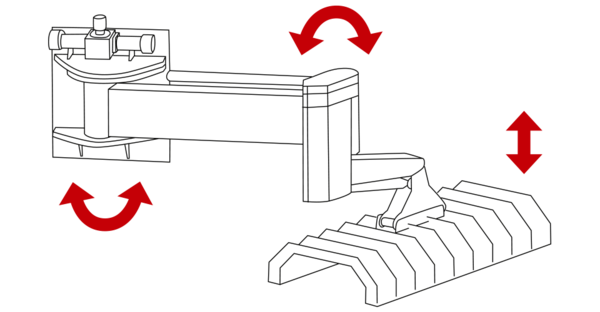

Movement types

The cover manipulator is mounted on the casthouse floor and the cover is moved by lifting and forward/backward movement

The cover manipulator is mounted on the casthouse floor and the cover is moved by lifting and slewing. In case of special requirement an additional turning of the cover can be implemented.

The cover manipulator is moving on rails fixed underneath the tuyere platform. An additional hydraulic cylinder is responsible for lifting and lowering of the cover

In case of layout restrictions the cover manipulator can be connected to main blast furnace column.

The cover manipulator in operational use

Best possible combination with TMT controls

Controls span from full automatic manless casthouse operation to simple manual operation. Specially developed algorithms like "soft touch", "interval ramming", intelligent hammer control, etc. provide complete process flexibility and record process data.

Get in Touch

Further information

If you have any requests, questions or needs, please don't hesitate to contact us. We will answer your inquiry as fast as possible.