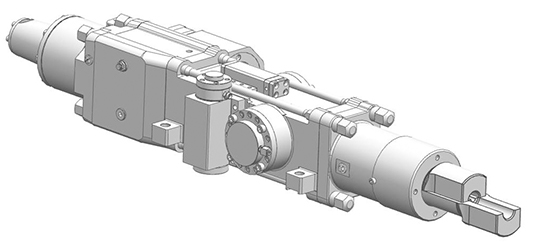

Taphole Opener

Smooth Drilling for

highest taphole protection

Your Benefits

Highest reliability, lowest lifecycle costs

Based on more than 5 decades of experience in design and manufacturing

Avoid sticking drill bars

Integrated reverse hammering guarantees drill bar pull out under any circumstances

One bit + bar

Proven one bit + bar per opening performance

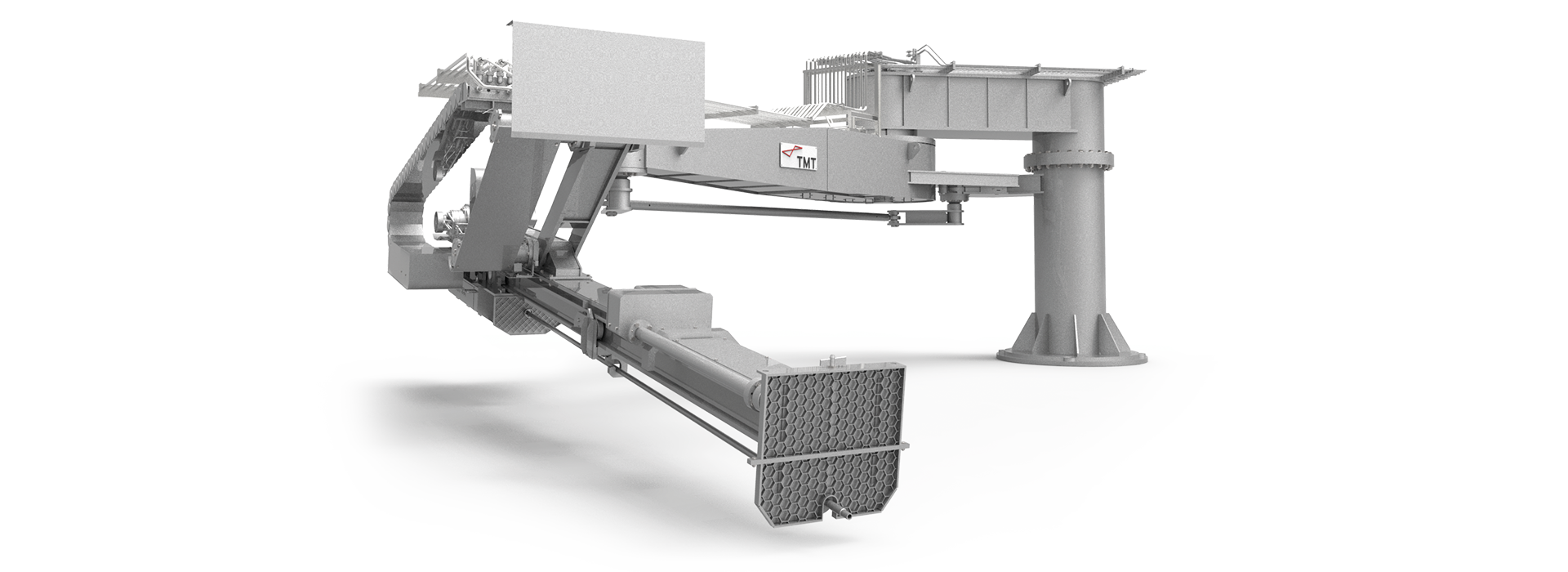

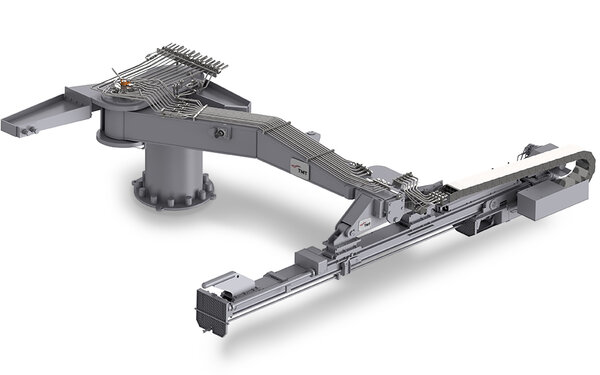

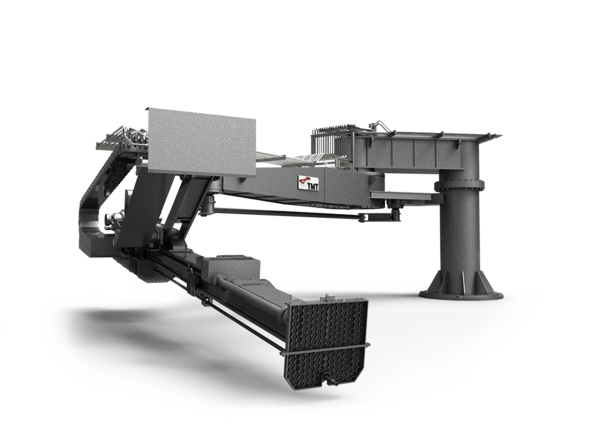

Layout Variants

The drill mast is moving at an inclined plane in order to reach the working point

At the end of the slewing motion of the taphole opener, the drill mast is tilted in order to reach the working point

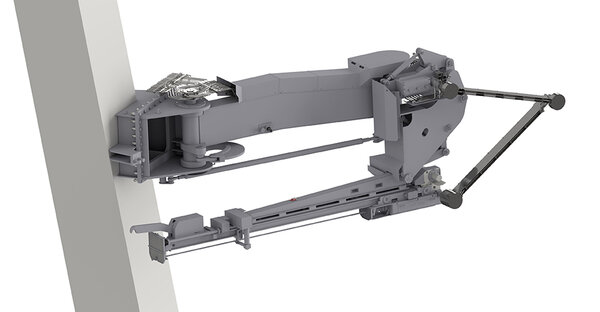

In most of the cases the taphole openers are supported by columns fixed at casthouse floor. In special cases the taphole opener can also be mounted on main BF column or underneath the tuyere platform. The way of fixation is always driven by casthouse layout situation and customer requirements.

World's only hammer with online performance adaptation: HS600

Full automatic operation available for highest level of taphole protection.

The taphole opener in operational use

Best possible combination with TMT controls

Controls span from full automatic manless casthouse operation to simple manual operation. Specially developed algorithms like "soft touch", "interval ramming", intelligent hammer control, etc. provide complete process flexibility and record process data.

Get in Touch

Further information

If you have any requests, questions or needs, please don't hesitate to contact us. We will answer your inquiry as fast as possible.