Combined Tapping Machines

Advanced Tapping

Technology

For Non-Ferrous and

Ferro-Alloy Furnaces

Based on our experience with more than 500 references, TMT is your partner for improving your tapping process. Different machine configuration types, from basic to premium, allow a customization to fully suit your requirements.

Safety and Flexibility

Avoids accidents on the casthousefloor and fits any furnace size and layout

Productivity and Reliability

Increase the availibility of your furnace and ensures trouble free tapping operation

Taphole Protection through Precision and Repeatability

Extend the lifetime of your tapholes and maintain a continuous tapping flow

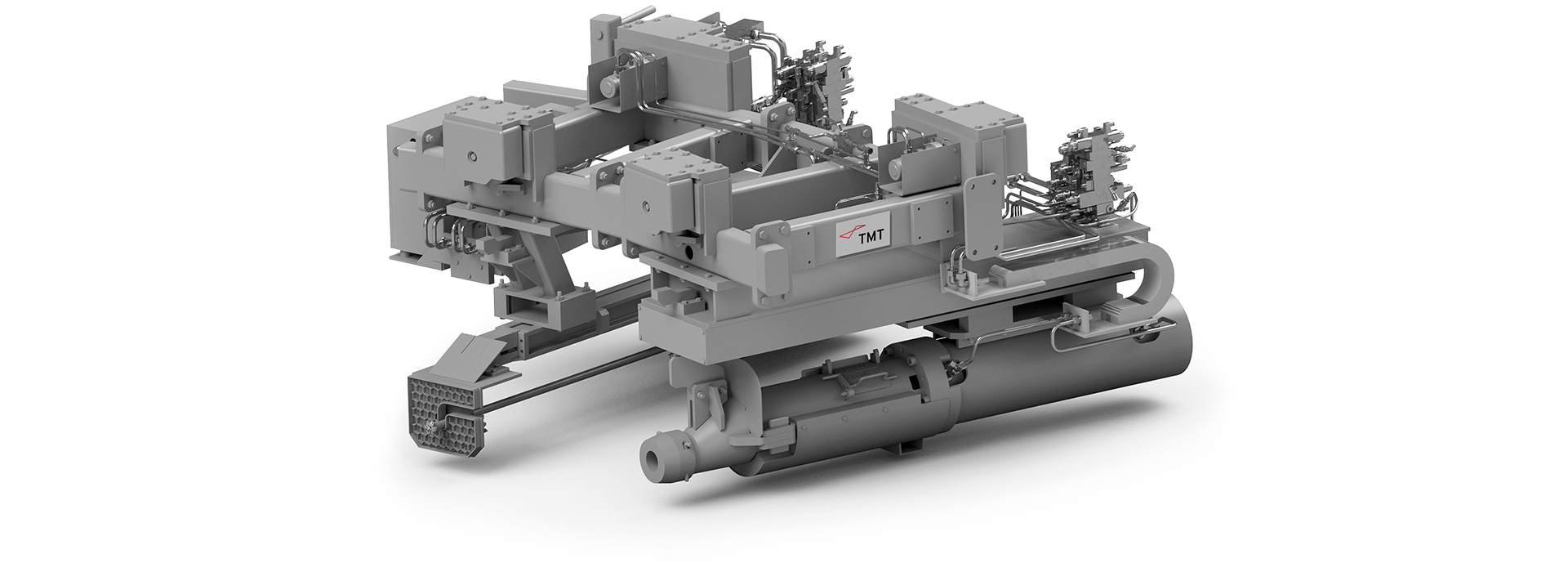

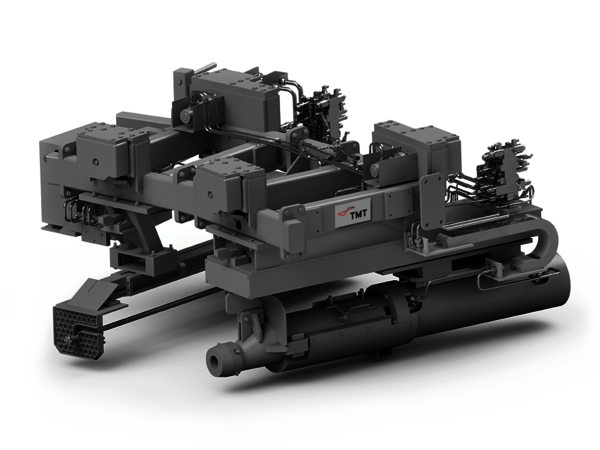

Layout variants

- Clay Gun and Taphole Drill arranged „side by side“

- Can serve multiple tapholes at multiple elevations

- No space blocked next to runners

- Extendable by optional equipment like rodding device, launder cranes, etc.

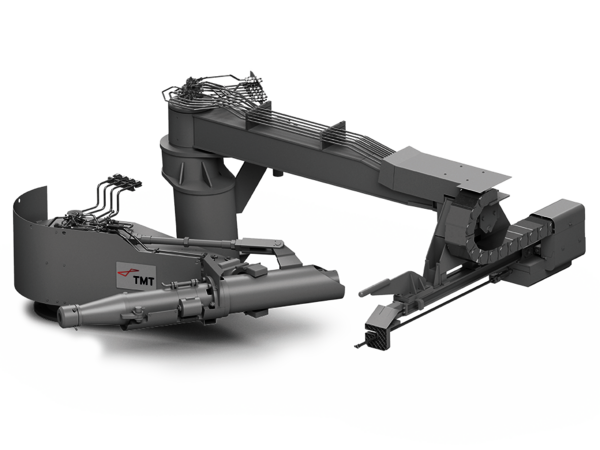

- Clay Gun superimposed above taphole drill

- For layouts requiring very narrow equipment arrangements

- Can serve multiple tapholes at multiple elevations

- No space blocked next to runners

- Reduced number of motions and drive units or cylinders due to fixed installation (no travel carriage)

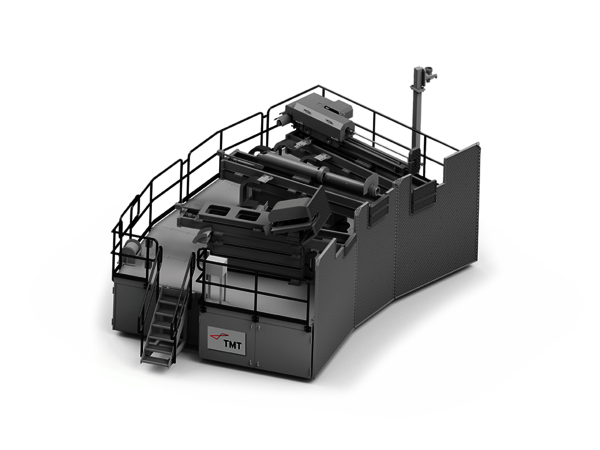

- Rugged design, serving one single taphole

- Multiple tapholes served by one machine

- No space blocked next to the runners

- Ideal for FeSi and Si furnaces with limited headroom above taphole

Combined Tapping Machines in operational use

Best possible combination with TMT controls

Controls span from full automatic manless casthouse operation to simple manual operation. Specially developed algorithms like "soft touch", "interval ramming", intelligent hammer control, etc. provide complete process flexibility and record process data.

Get in Touch

Further information

If you have any requests, questions or needs, please don't hesitate to contact us. We will answer your inquiry as fast as possible.